Site Closed Today

Edit: We regret to inform you that Meadow Orchard is closed today due to Storm Darragh.

In light of the yellow weather warning and the potential risk of falling branches, we have made the decision to close the site for safety reasons. We appreciate your understanding.

The activity

We will be preparing feedstock and loading a two drum retort, lighting the retort to produce a small batch of biochar. We’ll also have a small demonstration biochar cook stove. This is a great opportunity to see how a simple but effective no-cost retort can be assembled from readily available reclaimed materials.

Date: 7th December 2024

Time: 4:00pm – 6:00pm GMT

Location: Meadow Orchard Project, 151 Park Road, London, N8 8JD

Event is free to attend but donations towards the Meadow Orchard Project are welcome

Please Donate to help support The Meadow Orchard Project

Charity verified by Give A Little. GDPR, PCI & PCI-DSS Compliant Point of Donation.

What is Biochar

Biochar is a valuable soil additive, made from woody timber waste or other bio-waste material. Hardwood or softwood waste can be used, based on local availability. Often waste materials from crops can be used if those are readily available. At Meadow Orchard we use kiln-dried softwoods and hardwoods from a local woodworking shop. This is an otherwise waste material, free from preservatives, man made timber and other contaminants.

The process

Biochar or charcoal is produced by heating up woody material to around 450 – 500 degrees Celsius in the absence of oxygen, this process is known as pyrolysis. The lack of oxygen prevents the charred timber from igniting and turning into ash. The resulting char is largely pure carbon and is an excellent soil amendment. Charcoal can be produced in a simple cone pit or in a purpose made or simple two barrel retort. A similar process is used to produce either charcoal or bio char, charcoal is used as a fuel biochar is char which is then inoculated with soil microbiology by adding to a composting cycle and used as a soil conditioner.

The two types of retort at MOP

1) James Hookway J Type Rocket Stove Retort

This retort is based around a 205L Oil Drum with a 150mm (6″) diameter central flue. It produces a reasonable volume of charcoal in each burn. It is insulated with rockwool and the rocket stove increases the efficiency over a pit type charcoal burn.

In a Hookway retort, feedstock is packed inside the insulated drum around the inner flue, a close fitting lid is then fitted and capped tight with a band clamp. Once loosely loaded (to maintain air spaces for the wood gasses) feedstock is then added into the rocket stove flue. This is lit from the bottom and the heat from the stove pipe heats the feedstock around it inside the insulated drum, any moisture is driven out of the wood and the wood heats up and begins to off-gas volatile organic compounds or wood-gas.

A small pipe inside the retort funnels the resulting wood gasses back down into the burn chamber, these wood-gasses then ignite in the burn chamber which helps to sustain the burn, once heated to around 450 degrees the timber inside will begin to char and off-gas these flammable compounds. As the burn advances and the wood inside becomes char, which is largely purely carbon, there will be less smoke or woodgas to fuel the burn and the fire will die down. At this point the retort can be capped off, allowed to cool and then emptied.

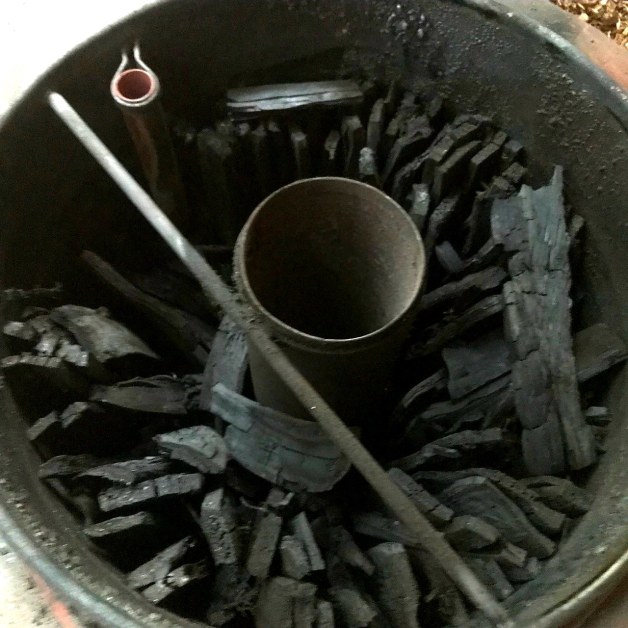

2) Two Barrel Charcoal Retort

This retort is of the TLUD type (Top -Lit Updraught) made from a 65L Oil drum with a smaller 25L drum fitted inside. The feedstock for the char is added to the smaller drum which then has the lid loosely wired on, this is placed inverted into the larger drum. Long thin dry feedstock is packed around the inner drum and a small pyramid shaped fire is built up on top of the drum.

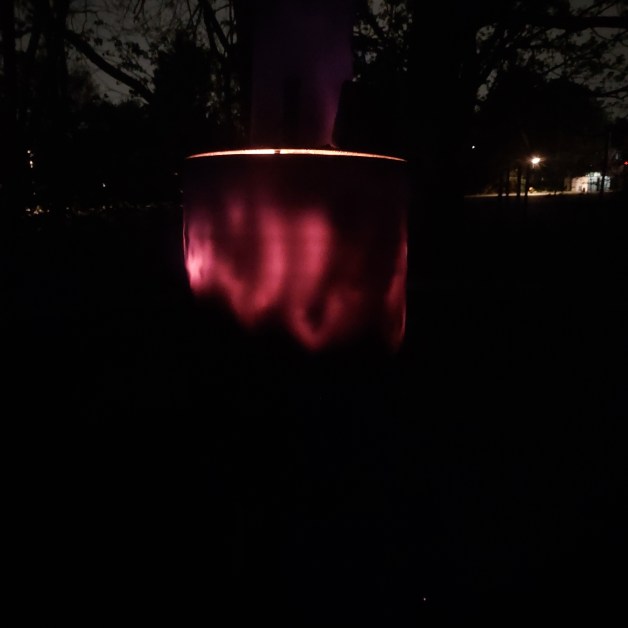

The retort, once loaded is lit from the top and the fire spreads downwards, charring the feedstock in the inner drum. A small gap around the lid of the inverted inner drum allows the wood gas to exit, where it then ignites inside the outer drum, further heating the inner drum. Since the wood gasses are burnt inside the burn chamber and inside the flue, these methods produce far less smoke than an open fire for example. Once up to temperature in retort mode the resulting exhaust from the flue should be clear, with just a heat-have and red jetting flame from the retort.

You must be logged in to post a comment.